Cartonrun is a packaging plant and corrugated box manufacturing company that needed to digitize and streamline its end-to-end operations.

They were managing complex production flows manually, across departments like inventory, purchase, production, and dispatch. The inefficiencies were adding up in the form of delays, miscommunication, and missed delivery timelines.

The client had outgrown spreadsheets, physical registers, and disconnected tools. They needed a centralized system to:

Above all, they wanted a system that was tailor-built for their real-world operations, not a generic ERP.

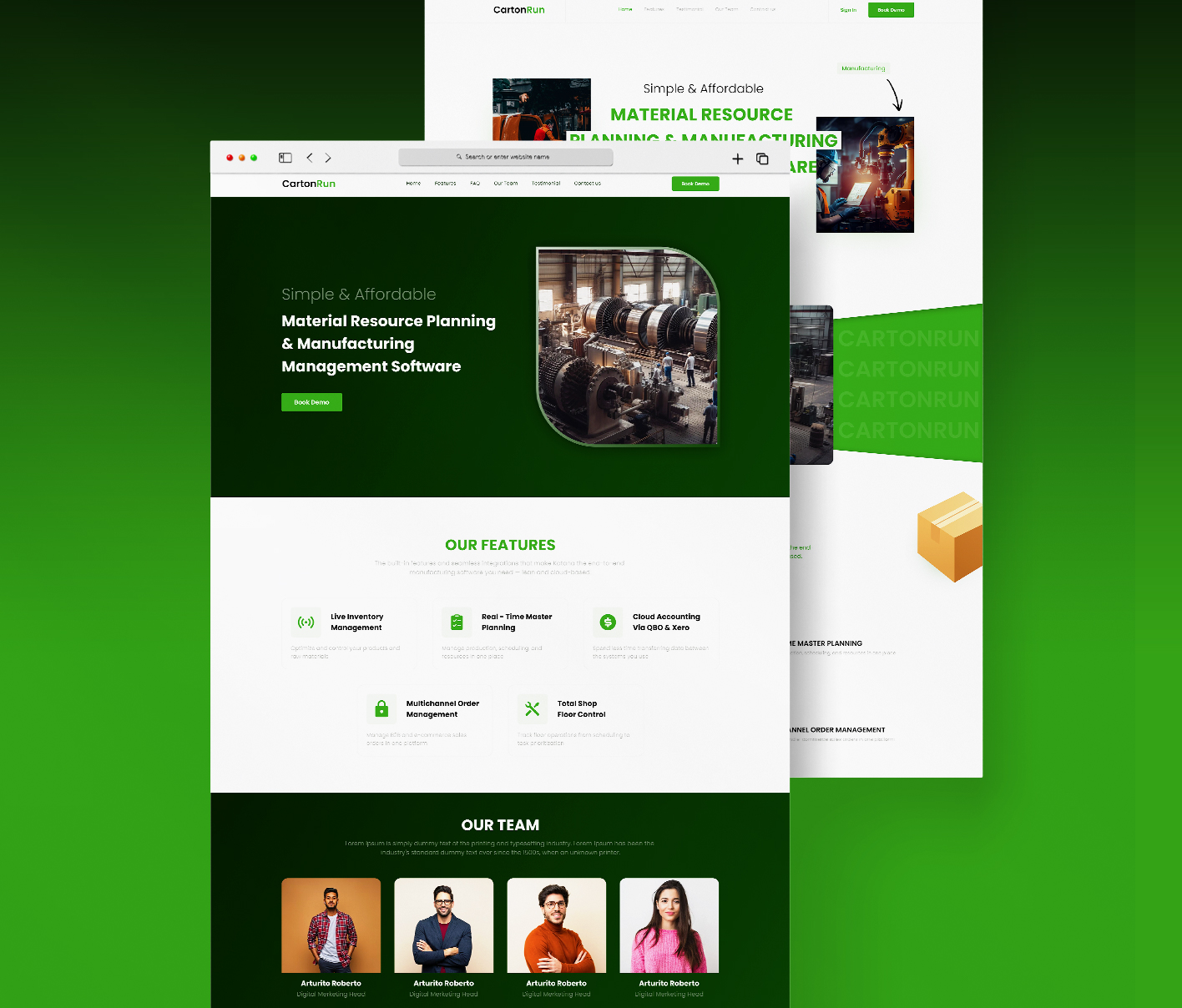

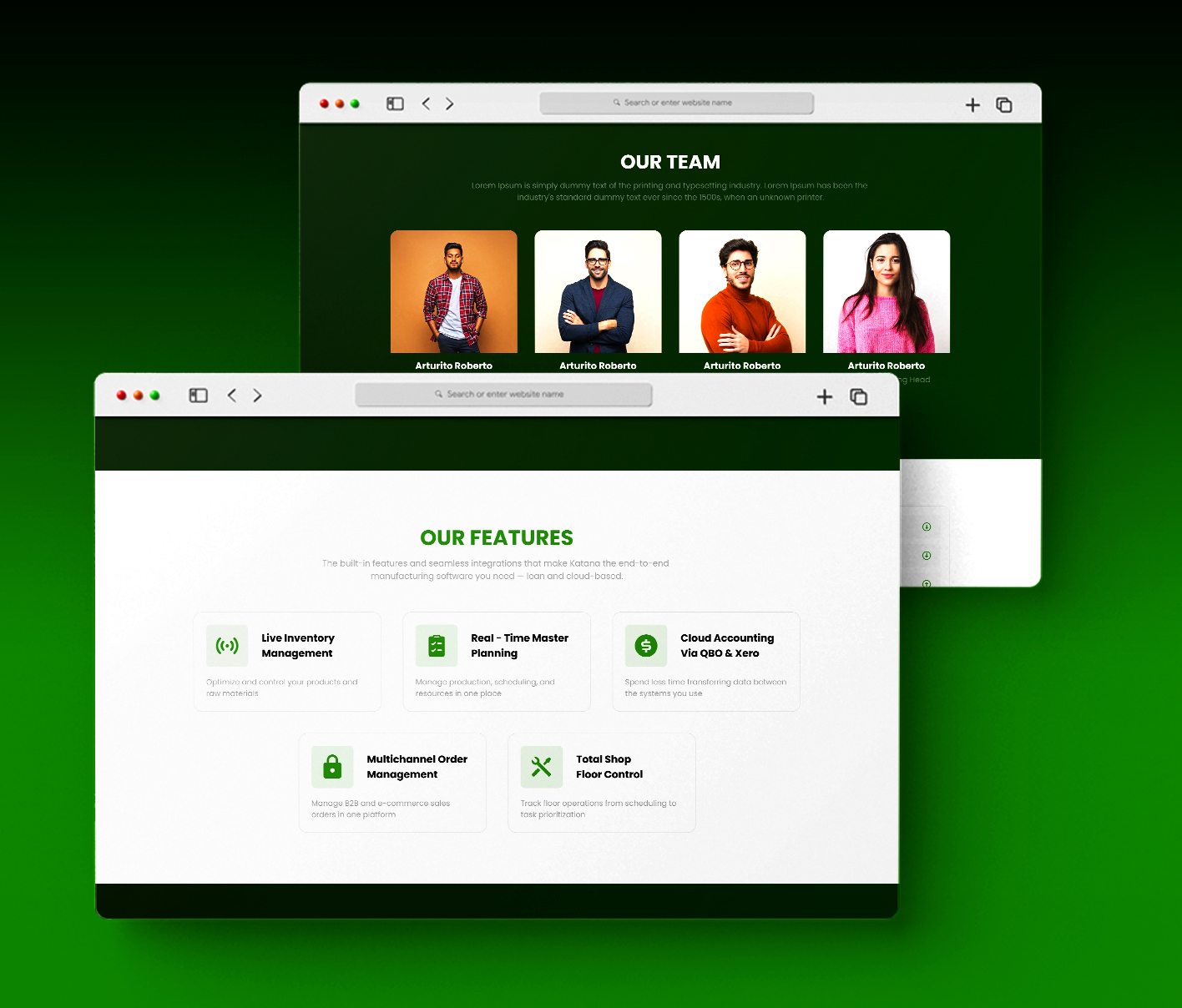

We built a modular, scalable Manufacturing Management System tailored to the client’s exact processes and terminology.

The platform was fully web-based, optimized for both desktop and tablet use in the factory setting.

After implementing Cartonrun’s MRP platform:

✅ 100% visibility into inventory and job status

✅ Reduced overstocking and last-minute material shortages

✅ Improved on-time delivery and batch tracking

✅ Faster production planning with real-time floor feedback

✅ Reduced manual errors, duplicate entries, and miscommunication

MRP tools only work when they match the actual rhythm of your factory. With Cartonrun, we proved that tailor-made digital infrastructure can streamline even the most complex production setups.

Whether you’re making boxes, bottles, or bearings, we can help digitize your factory floor without slowing it down.

Griphhy is known for its customized & innovative software solutions.

COPYRIGHT © 2025 GRIPHHY LLP. ALL RIGHTS RESERVED.